Carbon capture and storage (CCS) and carbon capture utilisation and storage (CCUS) have a number of technologies currently in use around the world:

- Post combustion carbon capture

- Pre combustion carbon capture

- Oxy-fuel combustion systems

- Direct air capture

Post combustion carbon capture

Post combustion carbon capture captures carbon dioxide (C02) from a flue gas that has been generated after the combustion of a carbon based fuel such as coal or natural gas.

Conventional fossil fuel power generation plants burn the coal or the natural gas with air to generate heat energy, which they then convert into electricity.

With much of Australia’s electricity generation coming from this process, the implementation of carbon capture technologies such as post combustion carbon capture is critical to the reduction of CO2 emissions.

The big challenge with post combustion carbon capture comes from separating the CO2, which is relatively low in concentration, from the high volume of nitrogen.

The concentration of C02 from a natural gas fired plant is approximately less than 4% by volume, compared to a C02 concentration of approximately 12-15% from coal based processes.

Industries that benefit include coal gasification, ethanol and fertiliser production, and natural gas processing. Manufacturing such as cement, iron and steel and pulp and paper. The process uses solvents (liquid) to separate the carbon dioxide (CO2) from the gas.

Other technologies such as sorbent based CO2 capture, membrane CO2 capture and novel concepts such a hybrid system of combining solvents and membrane are continuing to develop. Once the carbon has been captured it can be repurposed or sequestered underground for safe and secure storage.

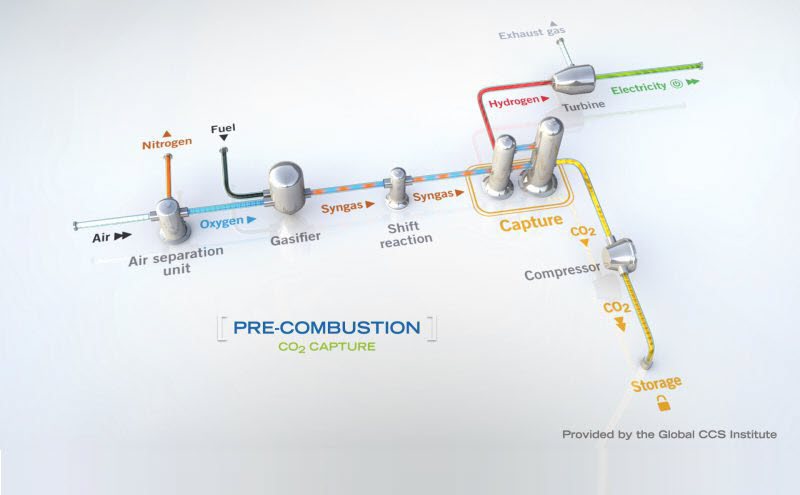

Pre combustion carbon capture

The pre combustion carbon capture technology is relatively new compared to post production carbon capture. The process converts fuel into a gaseous mixture consisting of hydrogen and CO2.

The CO2 is separated from the hydrogen and the hydrogen can be safely burnt to create electricity without producing any CO2 emission. The separation is a three step process involving an air separation unit, gasifier and shift reaction for the CO2 to be captured and the hydrogen separated and diverted.

The CO2 is then compressed for transport and storage. Just as the name suggests, the removal of the CO2 from the fossil fuel is done before combustion is completed.

Industries including fertiliser and cement processing factories, steel, iron and industrial processes such as natural gas processing benefit from the pre combustion carbon capture technology. Its disadvantage is an economic issue.

It is costly to install into existing infrastructure, however it is finding its place in new manufacturing development where CO2 emission legislation requires carbon capture technology to be included in the new infrastructure build.

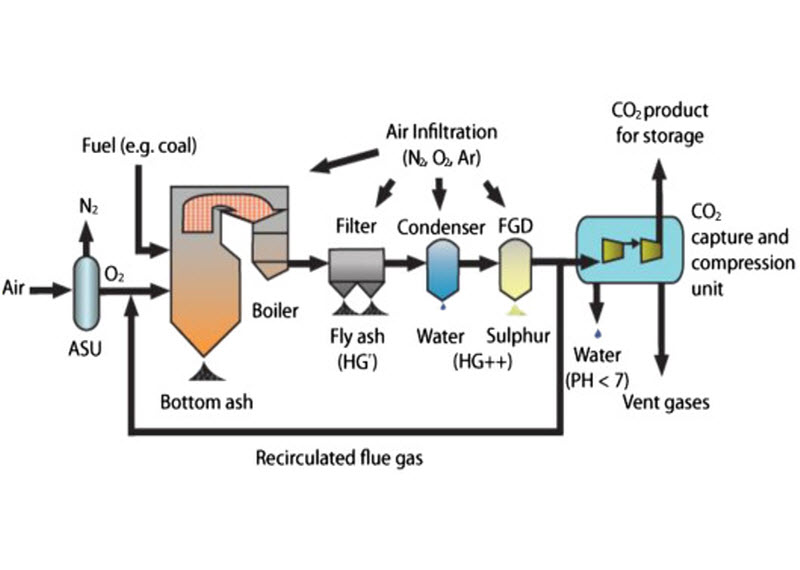

Oxy fuel combustion system

Oxy fuel combustion stems from the technology used in oxy cutting of heavy metals such as steel. The process involves burning the fossil fuel with nearly pure oxygen instead of air as used in traditional methods. To control the flame temperature, parts of the flue gas are recycled back into the boiler or furnace.

The recycled flue gas has secondary uses within the system improving efficiencies, however its main advantage in the story of carbon emissions is this process creates a flue gas that is highly rich in CO2 and can be easily captured for transportation and sequestration. Additionally, oxy fuel combustion creates approximately ¾ less flue gas than traditional air fuel combustion methods.

Direct air capture

This literally captures air from the atmosphere using a large series of fans that draw the air into a collector. The unit will generally sit on the rooftop of the intended facility. Inside the collector, the air passes over a filter membrane that has potassium hydroxide flowing over it.

A non-toxic solution, the chemical binds with the CO2 molecules, trapping them and forming a carbonate salt. The CO2 is separated and the purified air is released back into the atmosphere. The captured CO2 has a very high purity and can be transported for sequestration. It is much like the process of photosynthesis that plants and trees provide, only much faster and it can be installed at the source of high CO2 emitting industries.

CCS Energy has the expertise to advise and help implement carbon capture and storage technologies into your business. Small, medium or big, we can help you play your part in reducing carbon emissions now and into the future.

The role of CCS and CCUS is critically important to the health and future of our planet. CCS Energy is committed to forging your path toward net zero emissions. Our expertise can help clients set realistic targets and tap into additional asset value through carbon offset mechanisms available through various global emission trading schemes.

Our team members are CCS experts and well engineers, passionate about identifying efficient and cost-effective transition technology to capture and store carbon, and reduce your operation’s carbon footprint.

With years of technical experience in the petroleum industry, we can provide all aspects of technical design, project management and regulatory administration.

When your business is ready to do its part in reducing its carbon emissions footprint, give our team a call. We only offer the very best solutions and technical expertise.